|

|

|

INFORMATION DETAILS

ID: 13649942

|

Year: 2017

|

Make: Case IH

|

Model: Axial-Flow® 8240

|

Type: New

|

| MSRP:

N/A |

Engine Size - cc: N/A |

| Horsepower, Rated - hp (kW): | 480 (358) |

| Horsepower, Maximum - hp (kW): | 555 (414) |

| Power Boost - hp (kW): | 75 (56) |

| Engine Make: | Case IH FPT |

| Engine Model: | 12.9L |

| Number of Cylinders: | 6 |

| Emission Tier Level: | Tier 4B / Final |

| Fuel Tank Capacity - gal (L): | 297 (1125) |

| Feeder Width - in (mm): | 54 (1372) |

| Feeder Speed Variable: | Std |

| Feeder Reverser Control: | Electro-Hydraulic |

| Feeder Tilt Adjustment: | Std |

SELLER DESCRIPTION

|

Axial-Flow® 240 Series Combines

|

|

Case IH Axial-Flow 240 series leads the industry in productivity. With fewer drive components, an industry-leading AFS rotor and the ability to adapt to over 134 grain types, Axial-Flow combines are engineered for simplicity and reliability.

|

Capacity Matched Feeding: Increase Functional Performance

Get the job done right with high-capacity features and heavy-duty rotary feeding systems. Enhance crop flow and improve feeding into the combine, resulting in smooth crop flow and reduced wear.

|

|

Drive Systems: Shift Into the Model for You

Whether you want simplicity and convenience or superior control, Case IH Axial-Flow combines are available with the rotor technology that is right for you. Featuring our innovative Power Plus CVT combine drive that is belt-free and low maintenance, the design offers unique in-field capabilities to help you harvest more of what you grow.

|

|

Threshing and Separating: Control Your Harvest

We pioneered single rotor development back in the 1960s. Since then, refinements, enhancements and improvements have led to the pinnacle in rotor performance — the AFX rotor. The AFX rotor can be set into many configurations, adapting to both crop and threshing conditions.

|

|

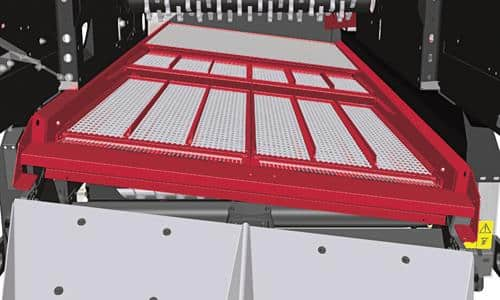

Cleaning: The Proof Is in the Sample

High-capacity combines need large high-capacity cleaning systems. Axial-Flow combines match cleaning system capacity to the size of the machine, providing superior productivity, grain sample quality and savings. The patented design of the Cross Flow™ cleaning system fan delivers consistently clean grain samples no matter the harvest condition. The result is exceptional grain quality, ideal for food-grade crops or crops grown by any producer who demands the most from his/her machine.

|

|

Residue Management: Maintain Easy, Effective Control

The Case IH residue management system is built to handle the tough residue associated with new crop genetics. This system delivers consistency across the larger header widths used on the Axial-Flow 240 series combines, helps prepare the ground for next year’s crop and can create consistent windrow formations and long straw for baling. From tillage to livestock demands, we offer the widest range of residue management features on the market.

|

|

|

Axial-Flow® 8240 Highlights

|

|

The Axial-Flow 8240 combine, with 480 hp and 410-bushel tank, provides unmatched horsepower and the performance you've come to expect from Case IH. |

|

Powerful Advantages

• 480 hp to power through demanding field conditions and handle heavy loads

• Fuel-efficient Case IH FPT 12.9 L engine for full Tier 4 B/Final compliance and 10% increase in fuel economy, on average

|

|

Greater Grain Capacity

• 410-bushel tank

• High unload rate of 4.0 bu/sec

• Optional dual drive unload system to turn off cross augers independent of unload auger, and to allow unload auger to be emptied with grain in tank

|

|

Advanced Farm Management

• AFS Connect™â€‹ 2.0 compatible

• Real-time dashboard access to your equipment on any device

• Track combines, grain carts and semis with up-to-minute harvest information

• Total control over your data - you decide who can see or can't see your data​

|

|

Residue Management

• Widest range of residue management options on the market

• Vertical Spreader provides optimal spread width for headers up to 45 feet

• Chopper provides six residue options to match residue handling requirements

• Dual Disc Spreader - Hydraulically driven variable speed for headers up to 40 feet

|

|

Unsurpassed Accuracy

• AFS Pro 700 display with variety tracking offers on-the-go yield monitoring and machine/guidance control

• AFS Variety Tracking for accurate records of seed varieties, inputs and performance; use data from up to 30 different seed varieties

• Automatic Crop Settings to have operator pick crop and have the combine set the basic functions

• Integrated yield and moisture monitoring sensors

|

|

Maximum Uptime

• Power Plus CVT drives mean less routine maintenance thanks to only three drive chains and six belts on the entire machine

• Industry leading 600 hours between oil changes

|

Back

|

|

|

|